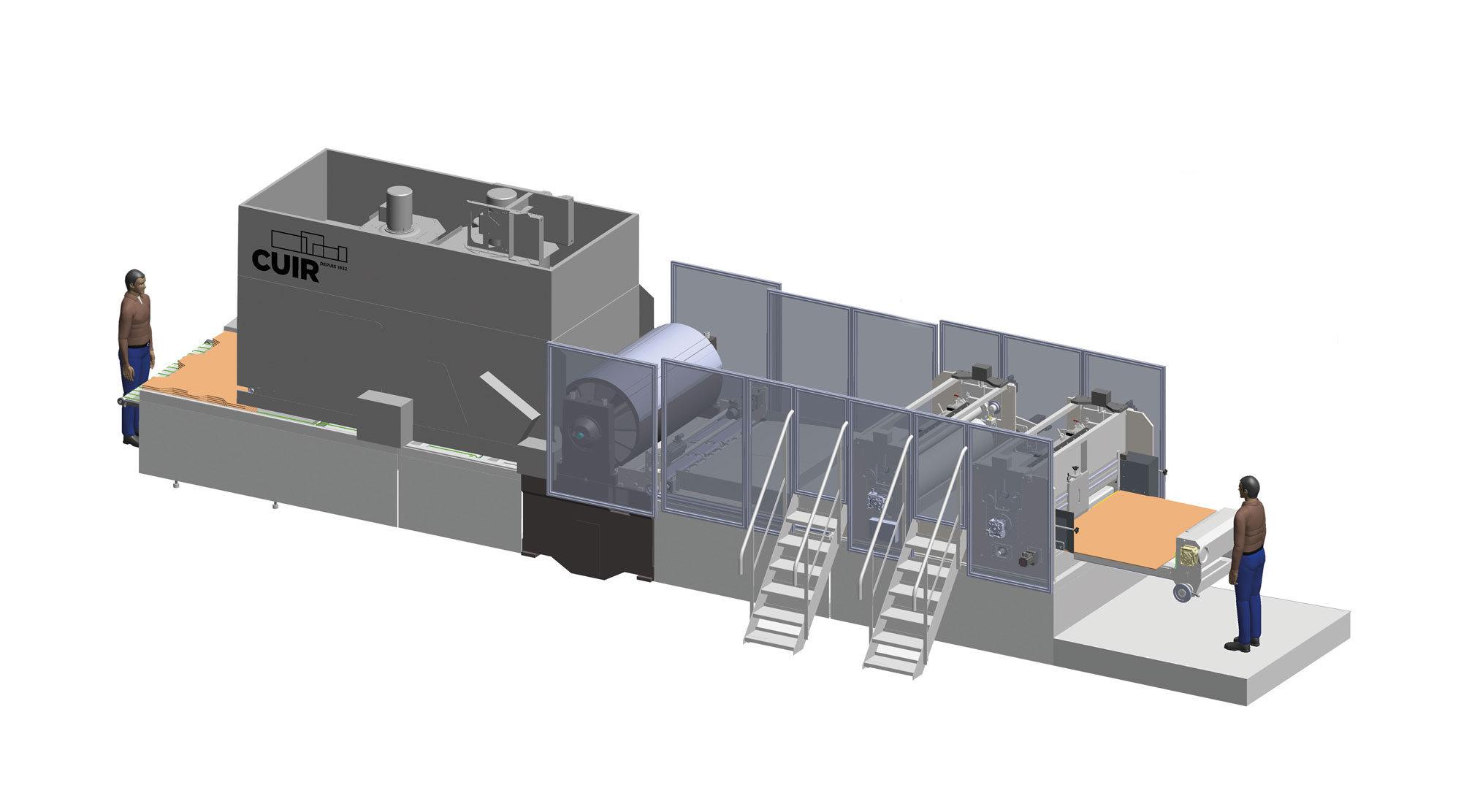

MINI CUIR

PRINTING AND DIE CUTTING IN LINE

MINI CUIR

PRINTING AND DIE CUTTING IN LINE

MINI CUIR die-cutter is a « cast in one piece » machine with two

printing units

Up to 3000 s/h

Sheet size Mini : 21.65×19.69’’

(550*500 mm)

Sheet size Maxi: 51.18×66.93’’

(1300*1700 mm)

Corrugated board from 0.04 to 0.35’’ (1 to 9 mm)

Maximum die-cut and print size 49.6’’x65’’ (1260*1650 mm)

Up to 3000 s/h

Sheet size Mini : 21.65×19.69’’

(550*500 mm)

Sheet size Maxi: 51.18×66.93’’

(1300*1700 mm)

Corrugated board from 0.04 to 0.35’’ (1 to 9 mm)

Maximum die-cut and print size 49.6’’x65’’ (1260*1650 mm)

WHAT MAKES THE DIFFERENCE

• Vacuum from the bottom, no pulling rolls, no board crush

• No power shaft, synchronized brushless motors

• Transport of board : vacuum and belts

• Centralized and memorized settings

• Reduced set-up time

• Remote maintenance through Internet

• Universal CUIR dies, re-use of your existing dies for MIEHLE, MRV, MARK I, MARK II

• 3 running speed :

– 3000 sh/h cut length < 29.5’’

– 2000 sh/h cut length ≥ 29.5 & < 43.3’’

– 1800 sh/h cut length ≥ 43.3 & < 49.6’’

• Printing and die-cutting in line

• Second to none cut to print registrer

• Vacuum feed roll feeder

• Top printing

• Absolute Chamber doctor blade

• Nickel coated plate and impression cylinders

• Stereo’s thickness according to the client

• Block of 2 printing units, synchronized brushless motors

• Cutting between a bed and a cylinder

• Super fast commissioning

• Overseas delivery in standard containers

• Multi-outs delivery

• No trim (2% of board savings)

• Sturdiness and reliability

• No special civil engineering (no pit)

• Option die-cutter only

• Printing improvement package :

– Compensation of printing elongations

– Re-registration option for litho laminated

product

– Re-registration before printer #2

• Vacuum from the bottom, no pulling rolls, no board crush

• No power shaft, synchronized brushless motors

• Transport of board : vacuum and belts

• Centralized and memorized settings

• Reduced set-up time

• Remote maintenance through Internet

• Universal CUIR dies, re-use of your existing dies for MIEHLE, MRV, MARK I, MARK II

• 3 running speed :

– 3000 sh/h cut length < 29.5’’

– 2000 sh/h cut length ≥ 29.5 & < 43.3’’

– 1800 sh/h cut length ≥ 43.3 & < 49.6’’

• Printing and die-cutting in line

• Second to none cut to print registrer

• Vacuum feed roll feeder

• Top printing

• Absolute Chamber doctor blade

• Nickel coated plate and impression cylinders

• Stereo’s thickness according to the client

• Block of 2 printing units, synchronized brushless motors

• Cutting between a bed and a cylinder

• Super fast commissioning

• Overseas delivery in standard containers

• Multi-outs delivery

• No trim (2% of board savings)

• Sturdiness and reliability

• No special civil engineering (no pit)

• Option die-cutter only

• Printing improvement package :

– Compensation of printing elongations

– Re-registration option for litho laminated

product

– Re-registration before printer #2